How to streamline the process of dimensioning and issuing shipments? Reliable trio

Automation of dimensioning and issuing of shipments

In a dynamic logistics environment where every element of the process must run smoothly, Efficiency of shipment handling is crucialThe more tasks you can automate, the greater the chance of avoiding errors, improving work organization and speeding up the entire chain of operations.

One of the places where delays and inaccuracies are still easy to find is when parcels are measured and weighed. Manually entering data, copying measurement results into the system, having to confirm each operation - all this takes time and engages the employee in activities that could be performed much more efficiently. This is where the problem comes in. an integrated solution that combines the functionality of an electronic measure, scale and panel computer — creating one, coherent system for quickly processing shipment information.

How does this solution work?

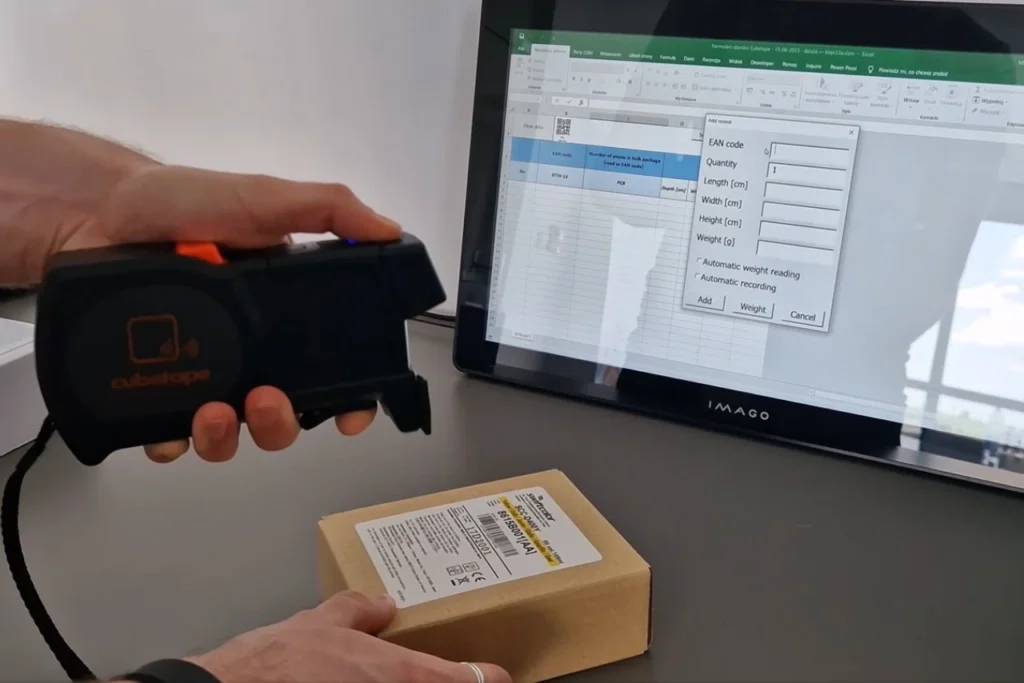

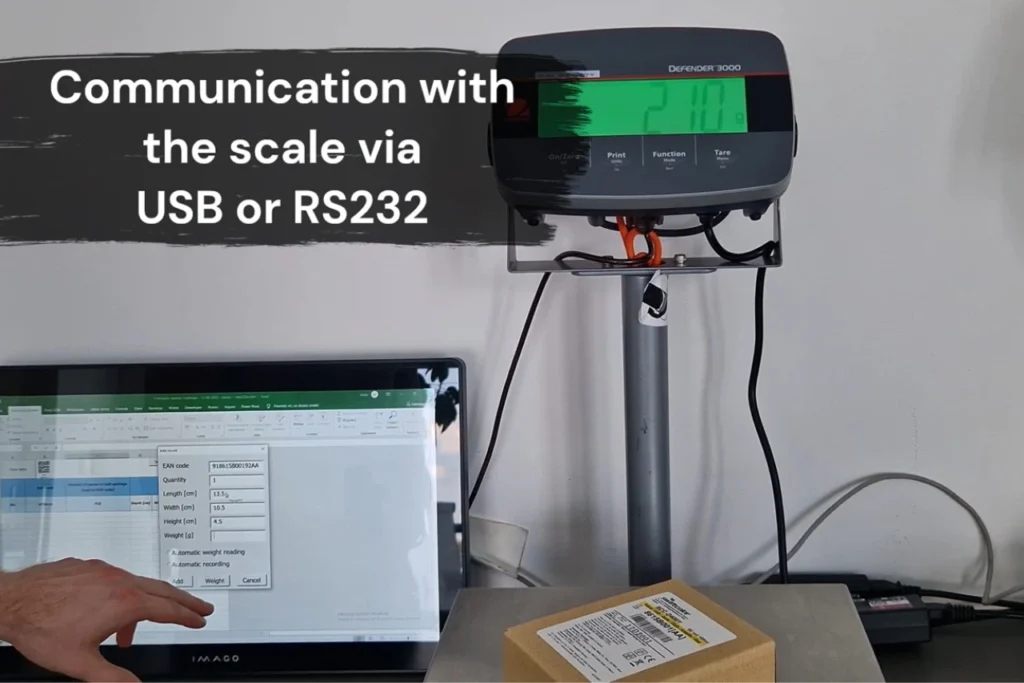

The whole thing is based on three devices: Cube Stage, ISK panel computer from Imago Poland and weight Ohaus. Cubetape is an electronic measuring cup, which connects to a computer via Bluetooth, to which the scale is connected by cable, via the RS232 port. Thanks to the dedicated application, the entire process takes place almost without the operator's participation - measurements are sent to the system automatically, without the need for manual entry.

The employee scans the package code and measures its dimensions. The data is immediately transferred to the computer. At the same time, the scale registers the weight of the shipment, and the system saves the full set of information. When the operator scans the next package, the data of the previous one is already saved, and the system smoothly moves on to the next measurement.

This approach allows for almost complete elimination of the need for computer operation during dimensioning – all information is transmitted and saved in the background. Moreover, automatic and accurate measurements reduce the risk of costly errors. Many logistics operators charge additional fees if the dimensions or weight of the package do not match the reality. Even a few centimeters of difference can mean a large surcharge – especially with a large number of shipments. Therefore, precision at this stage is not only a matter of order, but also real savings.

What does the company gain from such a solution?

The implementation of an integrated system for dimensioning and weighing translates into a number of benefits, especially where speed and accuracy are important. Among the most important advantages, it is worth mentioning:

- Data automation – the system itself records dimensions and weight, without employee involvement.

- Error reduction – measurements are not entered manually, so the risk of errors is reduced to a minimum.

- Saving time – the process is faster and more predictable.

- Easier integration with WMS systems – the data is ready for use in further stages of the logistics process.

- Better work organization – the employee can focus on operational tasks rather than on entering data into the computer.

This approach not only simplifies day-to-day operations, but also allows for greater control over the quality of shipment handling.

Who might find it useful?

This solution works particularly well in places where a large number of parcels are processed. It is used by, among others:

- courier and transport companies,

- logistics centers and e-commerce warehouses,

- manufacturers shipping goods directly to partners, customers or sales networks.

Regardless of the size of the company, anyone who wants to increase efficiency in packaging and preparing shipments can really benefit from implementing such a solution.

Simple, effective, no complications

What sets this system apart most is its intuitiveness and ease of implementation. It doesn't require major organizational changes or lengthy employee training. It's technology that truly simplifies work. All you need is panel computer, cubetape measure and scale.

Instead of entering data manually, you can let the entire process run automatically – faster, more accurately, and without unnecessary stress. And it is precisely this kind of work comfort that increasingly determines the operational success of companies.